MULTI STAGES HYDRATOR SERIES

Hydrated lime is the second most important product of the lime industry and modern industrial applications developed in the 20th century require many different qualities of lime, to be manufactured under strictly controlled conditions. In particular relatively new industrial uses, such as FGD, have required new product characteristics, from enhanced average fineness, to higher surface area and pore volume.

This has led to the needs to evolve and partly redesign hydration equipment and their ancillary components in order to meet the product quality demands on the one hand, and the emissions standards on the other.

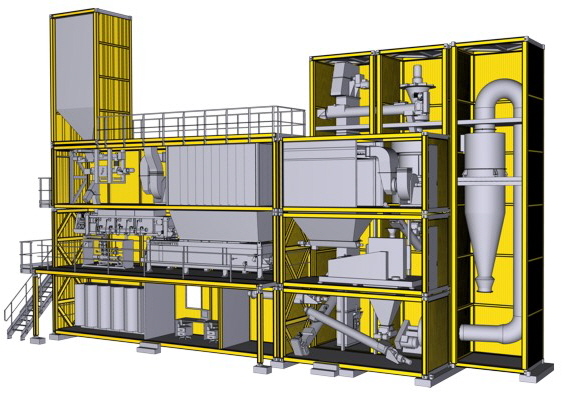

Cim-Hydrax-Compact® ![]()

A complete and autonomous industrial hydration plant, specially designed to be as small and compact as possible by eliminating unnecessary auxiliary machines and spaces, thus greatly reducing the CAPEX and preserving the contractual performance of the Hydrax.

The Cim-Hydrax-Compact® is available in different configurations to meet the maximum flexibility, reduce maintenance and running costs, while obtaining excellent qualities and outputs.

In order to get more from a smaller footprint, our Customer Care Service is able to advise the most adequate technical options according to laboratory tests and to the retrofitting space.

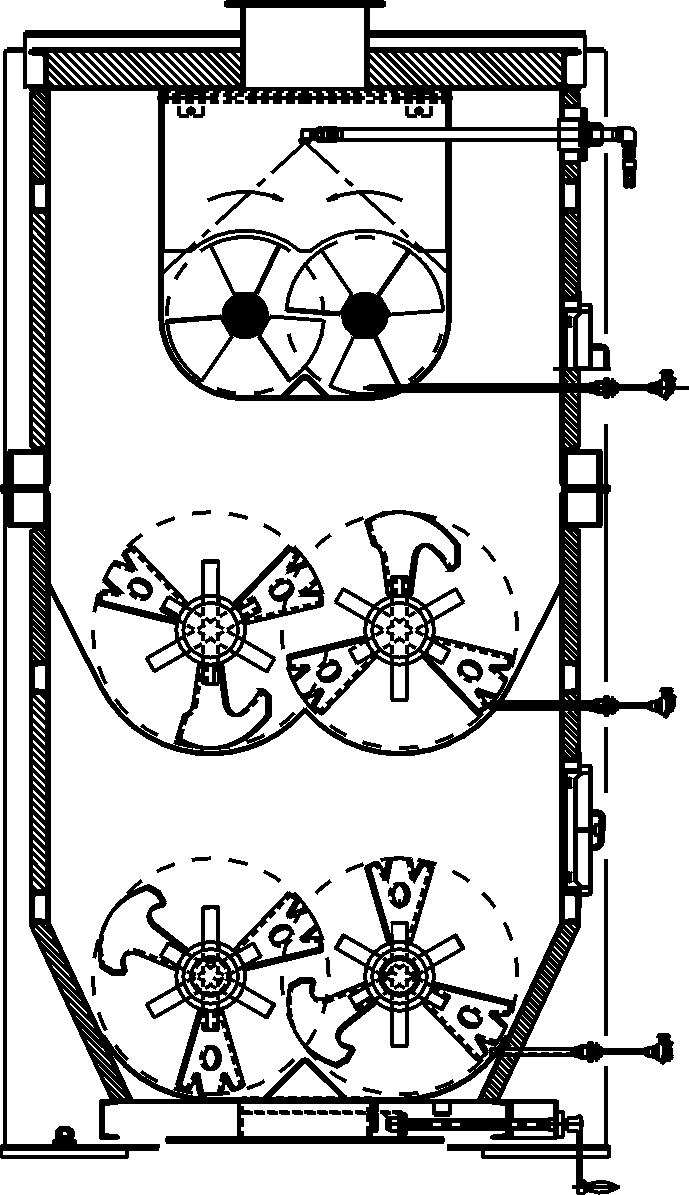

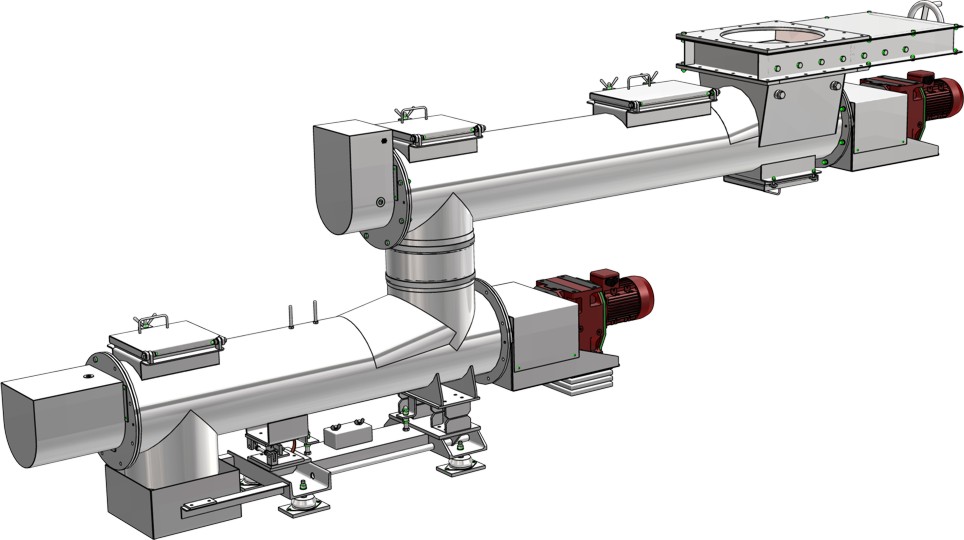

Pilot hydrator ![]()

An accurate scale down of the industrial machine for an exceptionally wide range of operating conditions.

Very effective testing campaignes at clients plants sites are possible.

The results of the tests are effectively used for the design and supply of the industrial scale hydrator which is best matching the client objectives.

Technical features

- production: up to 130 kg/h

- dimensions: L3800x660xH3850 mm

(including feeding & discharge screw conveyor and bag filter) - electric board dim.: 800x600x2100 mm

- installed power: 5 kW

- total weight: 1600 kg (including electric board)

Client should provide a quicklime feeding hopper above screw conveyor and a collection system of hydrated lime (e.g. a big bag), the electric power connection to the board and water connection to hydrator.

A range of specialized equipment has also been developed for the hydration process, namely:

Cim-Digidoser

the digital weighing feeder

Cim-Zeropoll

the dedicated bag house filter

Cim-Microsep

high efficiency separator

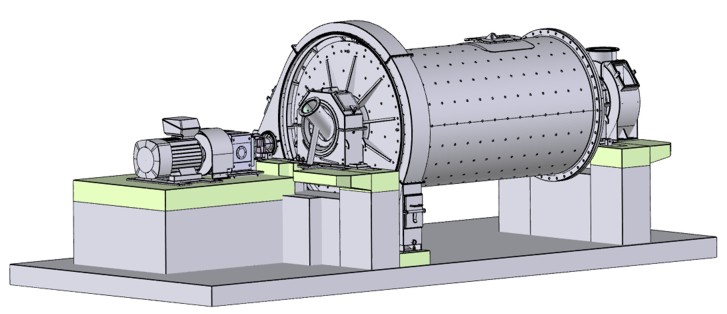

Tubular & vertical mills

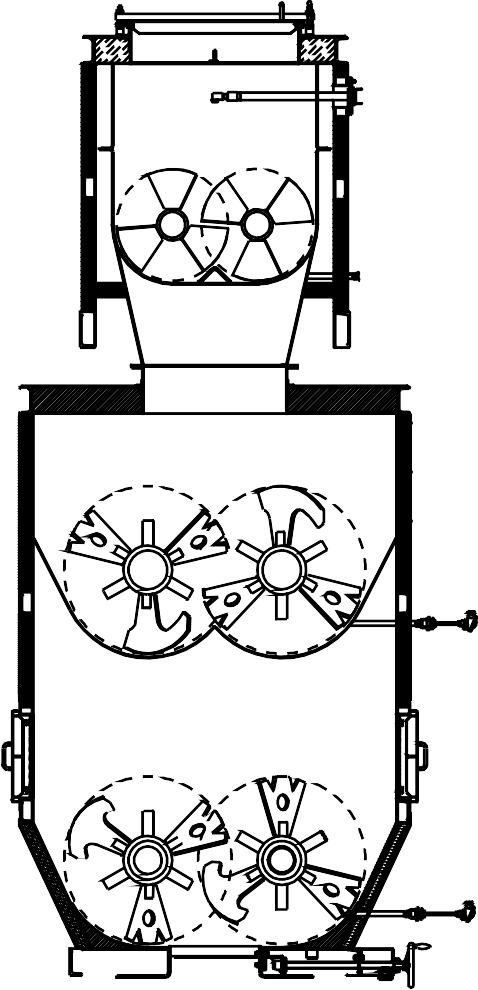

Hydration ancillary equipment ![]()

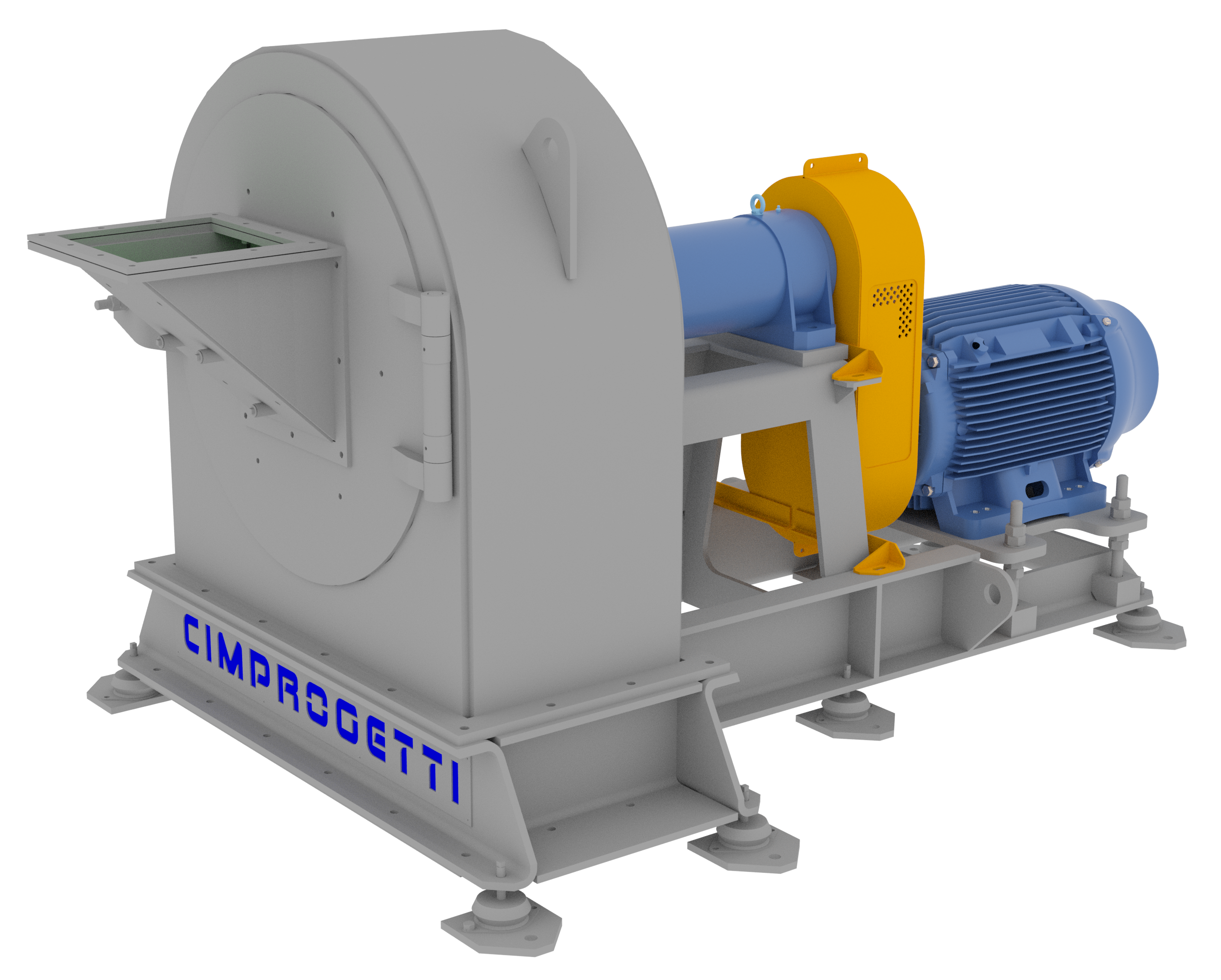

Cim-Cage disagglomerator

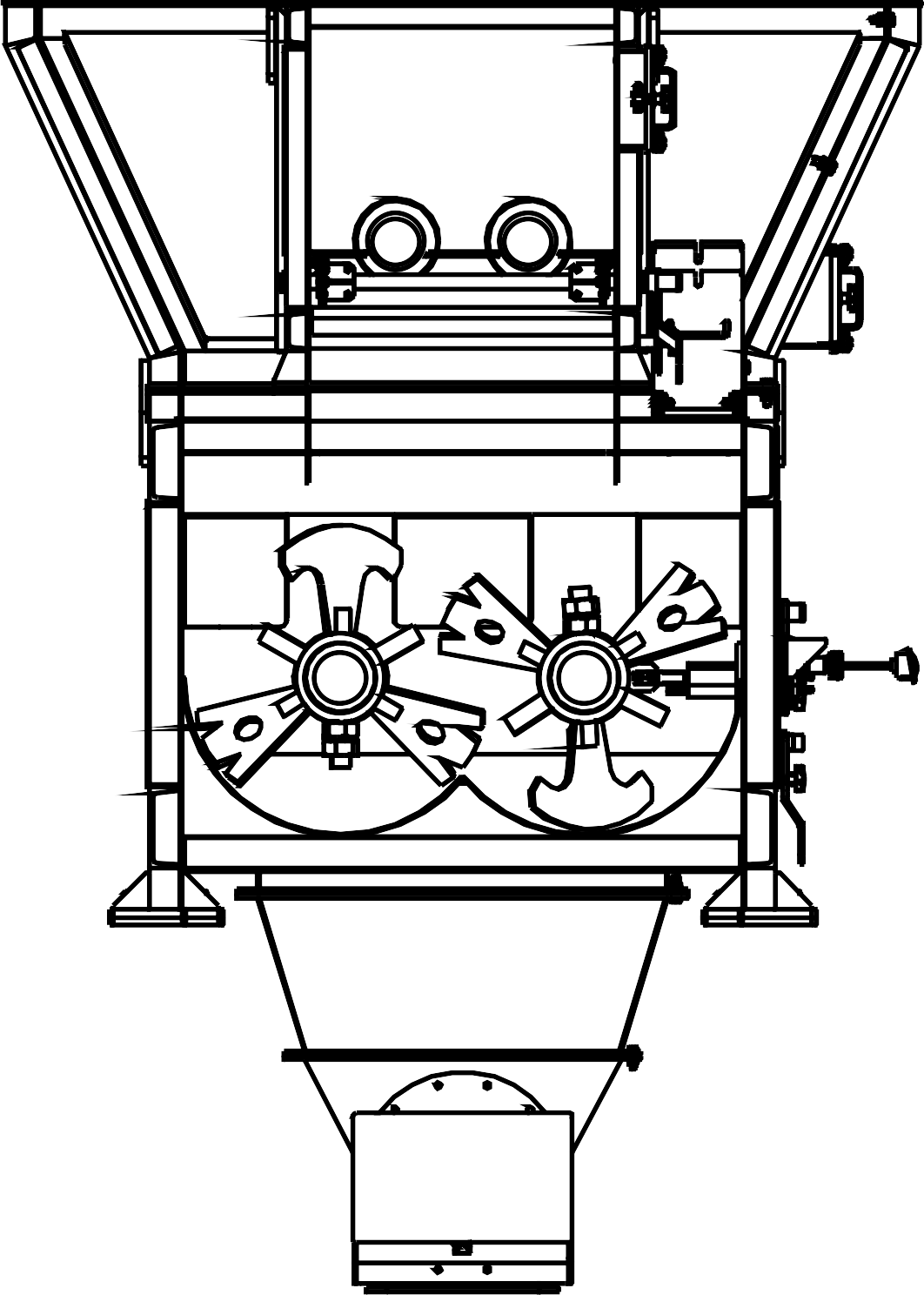

Hydrated lime with High B.E.T. specific surface ![]()

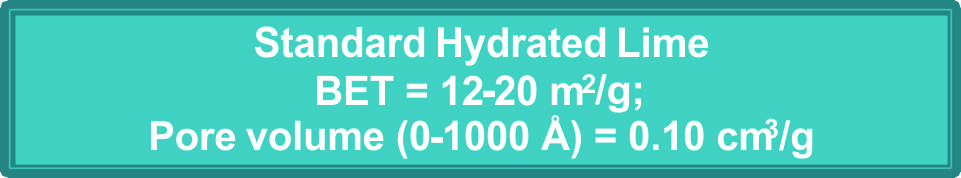

Depending on the type of limestone, of oxide, of the calcination and hydration technology it is possible to obtain a wide product qualities spectrum, having different specific surfaces and different abilities to reduce polluting gases.

Cimprogetti has developed test protocols calibrated according to the characteristics of the raw material and makes available a scale down pilot hydrator able to execute very effective testing campaignes at clients’ plants.

The results of the tests are effectively used for the design and supply of the industrial scale hydrator, which is best close tracking of process conditions and matching the client objectives.

The specific BET surface is a fundamental parameter required to estimate the absorption / purification capacity of gases / fumes by calcium hydroxide Ca(OH)2.

The Pilot Plant for High BET production is made available on a rental basis to be defined - Client to provide raw material and utilities.

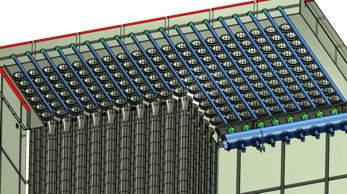

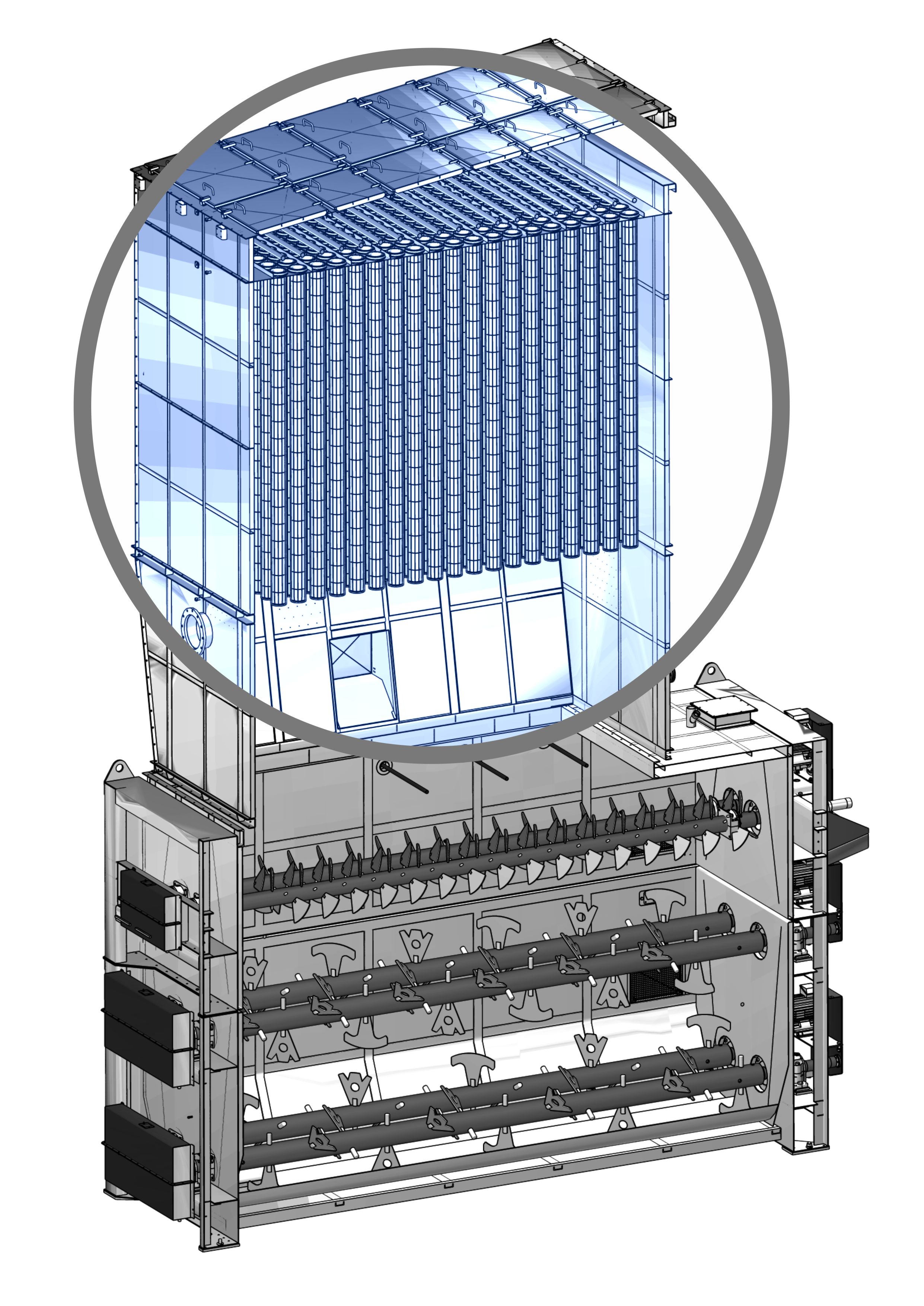

Enhance your filter system

EU regulation and local authorities will reduce the dust emission limit values.

Cimprogetti filtering technology is, in compliance with the most stringent EU BAT practices, guaranteeing dust emission lower than 10mg/Nm3.

OUR SERVICES

|

SITE SURVEY |

KNOW-HOW |

INSTALLATION |

|

Determine the available installation area and related potential constraints |

Identify and supply a bespoke technical solution |

Supervise during installation of the retrofit equipment |

If you are interested to know more about this opportunity and services, please feel free to contact our Sales Manager without any obligation ![]()

For the sake of guaranteeing smoothness and continue operation to your business, it is suggestible you plan in due time this necessary upgrade.

Cimprogetti is glad to put at your service our 50+ years experience and undisputable worldwide leadership in Hydration Technology to study together the best solution tailored to your plant.

Our technology is applicable both to Cimprogetti's hydrators and other brands.